Engaged in drying, pharmaceutical, food and other equipment manufacturing professional manufacturers

086-519-88608989

Overview:Working principle The hot air enters the bottom of the dryer tangentially, and is driven by the agitator to form a powerful rotating wind field. The paste material enters the dryer from the screw feeder. Under the strong action of the high-speed rotat…

Working principle

The hot air enters the bottom of the dryer tangentially, and is driven by the agitator to form a powerful rotating wind field. The paste material enters the dryer from the screw feeder. Under the strong action of the high-speed rotating stirring blade, the material is dispersed under the action of impact, friction and shearing force. The block material is quickly crushed, fully contacted with hot air, and heated ,dry. The dehydrated dry material rises with the hot air flow, and the grading ring traps large particles, and the small particles are discharged from the center of the ring to the outside of the dryer and recovered by the cyclone separator and dust collector. The incomplete or large materials are thrown to the wall by centrifugal force. , And fall to the bottom to be crushed and dried.

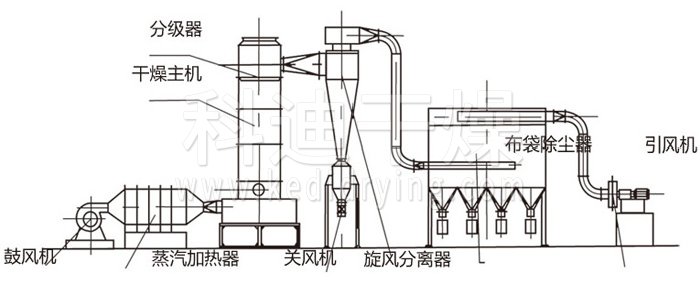

Schematic

Performance characteristics

◎The organic combination of swirling, fluidization, spouting and crushing classification technology.

◎Compact equipment, small size, high production efficiency, continuous production, realizing "small equipment, large production".

◎High drying strength, low energy consumption and high thermal efficiency.

◎The material residence time is short, the finished product is of good quality, and it can be used for drying heat sensitive materials.

◎Negative pressure or micro-negative pressure operation, good airtightness, high efficiency, eliminating environmental pollution.

Adapt to materials

Organic matter: Atrazine (pesticides), lauric acid, benzoic acid, benzoic acid, bactericide, sodium oxalate, cellulose acetate, organic pigments, etc.

Dyestuffs: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various azo dye intermediates.

Inorganic substances: borax, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony trioxide, various metal hydroxides, various heavy metal salts, synthetic cryolite, etc.

Food: soy protein, gelatinized starch, wine tank, wheat sugar, wheat starch, etc.

Technical specifications

| Model | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| Host inner diameter mm | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Air volume M3/h | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| Evaporated water kg/h | 12-17 | 40-70 | 80-150 | 150-250 | 230-450 | 300-600 | 600-1000 | 1000-1500 |

| Installed capacity kw | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Maximum height m | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Area m2 | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note: 1. The amount of water evaporation is the water evaporated per hour when the inlet air temperature is 180oC and the outlet air temperature is 80oC.

2. In addition to the above models, special designs can be made for users,

3. The above installed capacity is a standard package, and the power package can be significantly reduced according to different materials.

Processing materials and characteristics (based on type 6 flash evaporation)

| Material name | Stearic acid | Aluminum hydroxide | Zinc carbonate | Insecticide list | TMTD | DSD acid | Iron Oxide Red | Antimony Dioxide | Cuprous chloride | White too black |

| Inlet air temperature oC | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| Initial moisture content % | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| Final moisture content % | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| Actual drying capacity kg/h | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Material name | Accelerator |

Oil-soluble ink |

Manganese zinc oxide |

Phthalocyanine Blue |

Calcium Citrate |

Superfine calcium carbonate |

Mud treatment agent |

Sodium Dioxyisocy- anurate |

Sodium trioxyisocy- anurate |

|

Inlet air temperature oC |

150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

|

Initial moisture content % |

60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

|

Final moisture content % |

0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

|

Actual drying capacity kg/h |

80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |

Among the many drying equipment, spray drying equipment is one of the most widely used drying equipment, which is a drying equipment for proc…

When granular materials are dried in an ordinary fluidized bed dryer, the particles of the materials should be uniform and have certain speci…

The fruits and vegetables are sliced and dehydrated to become dehydrated fruit and vegetable slices. After being vacuum packed, this kind of …

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the world’s energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a larg…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…