Engaged in drying, pharmaceutical, food and other equipment manufacturing professional manufacturers

086-519-88608989

Overview:Product descriptionTray continuous dryer is an efficient conductive continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, …

Product description

Tray continuous dryer is an efficient conductive continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. It is widely used in chemicals, medicine, pesticides, food, feed, and agriculture. Drying operations in industries such as by-product processing. It is well received in practice in various industries. Now it produces three types of atmospheric pressure, airtight, vacuum, 1200, 1500, 2200, 3000 four types, A (carbon steel), B (stainless steel in contact with materials), C (on the basis of B, add steam pipe The road, main shaft and bracket are made of stainless steel, and the cylinder and cover are lined with stainless steel). Three kinds of materials, a drying area of 4~180m 2, a total of hundreds of models of series products, and can provide matching auxiliary equipment, which can meet the needs of users for drying various materials.

Working principle

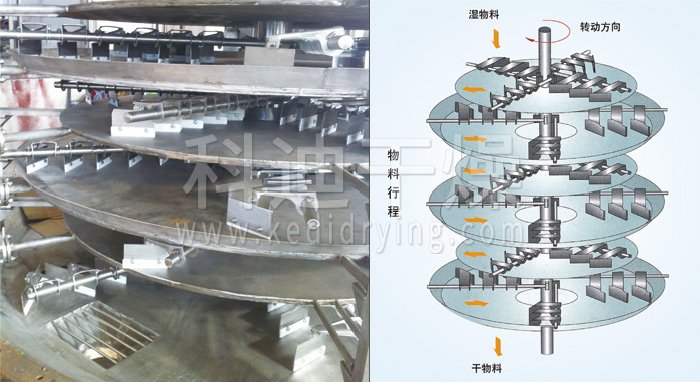

Wet materials are continuously added to the drying plate on the first layer of the upper part of the dryer from the feeder, and the rake arm with the rake blades rotates to make the rake arm rotate to make the rake blades continuously dig the material. The material flows through the surface of the drying plate along an exponential spiral. The material on the small drying plate is moved to the outer edge and falls on the outer edge to the outer edge of the large drying plate below. On the large drying plate, the material moves in and falls from the middle. The material opening falls into the small drying pan on the next layer. The large and small drying trays are arranged alternately up and down, so that the material can continuously flow through the entire dryer. A heating medium is introduced into the hollow drying plate. The heating medium is in the form of saturated steam, hot water and heat-conducting oil. The heating medium enters from one end of the drying plate and exits from the other end. Dried materials fall from the bottom drying plate to the bottom of the shell, and then are moved to the discharge port by the harrows for discharge. The moisture escapes from the material and is discharged through the moisture discharge port provided on the top cover. The moisture of the vacuum type disc dryer is discharged from the vacuum pump port provided on the top cover. The dry materials discharged from the bottom layer can be directly packaged. By adding finned heater, solvent recovery condenser, bag filter, dry material backmixing mechanism, induced draft fan and other auxiliary equipment, it can improve its drying production capacity. Dry paste and heat sensitive materials can be easily recovered Solvent, and can perform pyrolysis and reaction operations.

Performance characteristics

(1) Easy regulation and strong applicability

◎By adjusting the thickness of the material layer, the spindle speed, the number of harrow arms, the type and size of the harrow blades, the drying process can be better.

◎Each layer of the drying tray can be heated or cooled by heating or cooling the material through the heating or cooling medium alone, and the material temperature control is accurate and easy.

◎The residence time of materials can be adjusted accurately.

◎Single flow direction of materials, no back-mixing phenomenon, uniform drying, stable quality, no need for re-mixing.

(2) Simple and easy operation

◎The driving and stopping operation of the dryer is very simple.

◎After the feeding is stopped, the raking leaves of the conveying material can quickly empty the material in the dryer.

◎Through the special sight glass of the large inspection door, the inside of the equipment can be cleaned and observed carefully.

(3) Low energy consumption

◎The material layer is very thin, the spindle speed is low, the material conveying system requires low power and low power consumption.

◎Drying by conduction heat, high thermal efficiency and low energy consumption.

(4) The operating environment is good, the solvent can be recycled, and the dust emission meets the requirements

◎Normal pressure type: Due to the low air velocity in the equipment and the high humidity distribution in the equipment, it is difficult for dust to float to the top of the equipment, so the exhaust from the top wet exhaust port contains almost no dust.

◎Closed type: equipped with solvent recovery device, which can easily recover the organic solvent in the wet gas. The solvent recovery device is simple and the recovery rate is high. For flammable, explosive, toxic and easily oxidized materials, nitrogen can be used as a moisture-carrying gas for closed-circuit circulation to make it safe to operate. Especially suitable for drying flammable, explosive and toxic materials.

◎Vacuum type: A disc dryer operated under vacuum, especially suitable for drying heat sensitive materials.

(5) Easy installation and small floor space

◎The dryer leaves the factory as a whole and is transported as a whole. It only needs to be hoisted in place, and the installation and positioning are very easy.

◎Due to the layered arrangement and vertical installation of the drying plate, even if the drying area is large, the floor space is small.

Technical characteristics

(1) Drying plate

◎Design pressure: generally 0.4MPa, the upper limit can reach 1.6MPa.

◎Working pressure: generally ≤0.4MPa, the upper limit can reach 1.6MPa

◎Heating medium: steam, hot water, heat transfer oil, hot water heating at 100℃, 100℃~150℃ saturated steam or superheated steam ≤0.4MPa, 150℃~320℃ heating oil For heating, electricity, heat-conducting oil, molten salt, etc. can be used for heating when >320℃.

(2) Material delivery system

◎Spindle speed: 1-10 rpm, electromagnetic or frequency conversion stepless speed regulation.

◎Rake arms: There are 2-8 rake arms fixed on the main shaft on each drying plate.

◎Rake leaves: hinged on the rake arm, can float up and down with the plate to keep contact, and there are many forms.

◎Rolling: For materials that are easy to agglomerate and need to be crushed, adding rollers at appropriate positions can enhance the heat transfer and drying process.

(3) The shell has three types: normal pressure, airtight and vacuum

◎Atmospheric pressure type: cylindrical or octagonal prism type, with two structures of integral and split. The main pipeline of the heating medium inlet and outlet can be inside the shell or outside the shell.

◎Closed type: cylindrical shell, can withstand 5Kpa internal pressure, the main pipeline of heating medium inlet and outlet can be inside or outside the shell.

◎Vacuum type: Cylindrical shell, the design pressure is 0.1Mpa, the main pipeline of heating medium inlet and outlet is in the shell.

(4) Air heater

Generally used in the case of large evaporation to enhance drying efficiency.

Adapt to materials

Drying Pyrolysis Combustion Cooling Reaction Sublimation

Organic chemical products, inorganic chemical products, medicine, food, feed, fertilizer

| Specification | Outer diameter (mm) | Height (mm) | Dry area (m2) | Power (Kw) |

| 1200/4 | Φ1850 | 2718 | 3.3 | 1 |

| 1200/6 | 3138 | 4.9 | ||

| 1200/8 | 3558 | 6.6 | 1.5 | |

| 1200/10 | 3978 | 8.2 | ||

| 1200/12 | 4398 | 9.9 | 2.2 | |

| 1500/6 | Φ2100 | 3022 | 8.0 | |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3.0 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| 2200/6 | Φ2900 | 3319 | 18.5 | |

| 2200/8 | 3739 | 24.6 | ||

| 2200/10 | 4159 | 30.8 | 4.0 | |

| 2200/12 | 4579 | 36.9 | ||

| 2200/14 | 4999 | 43.1 | 5.5 | |

| 2200/16 | 5419 | 19.3 | ||

| 2200/18 | 5839 | 55.4 | 7.5 | |

| 2200/20 | 6259 | 61.6 | ||

| 2200/22 | 6679 | 67.7 | 11 | |

| 2200/24 | 7099 | 73.9 | ||

| 2200/26 | 7519 | 80.0 |

| Specification | Outer diameter (mm) | Height (mm) | Dry area (m2) | Power (Kw) |

| 2500/6 | Φ3150 | 3319 | 26.3 | 4 |

| 2500/8 | 3739 | 35 | ||

| 2500/10 | 4159 | 43.8 | 5.5 | |

| 2500/12 | 4579 | 52.5 | ||

| 2500/14 | 4999 | 61.3 | 7.5 | |

| 2500/16 | 5419 | 70 | ||

| 2500/18 | 5839 | 78.8 | 11 | |

| 2500/20 | 6259 | 87.5 | ||

| 2500/22 | 6679 | 96.3 | ||

| 2500/24 | 7099 | 105 | 13 | |

| 2500/26 | 7519 | 113.8 | ||

| 3000/8 | Φ3800 | 4050 | 48 | 11 |

| 3000/10 | 4650 | 60 | ||

| 3000/12 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 | |

| 3000/28 | 10050 | 168 |

Among the many drying equipment, spray drying equipment is one of the most widely used drying equipment, which is a drying equipment for proc…

When granular materials are dried in an ordinary fluidized bed dryer, the particles of the materials should be uniform and have certain speci…

The fruits and vegetables are sliced and dehydrated to become dehydrated fruit and vegetable slices. After being vacuum packed, this kind of …

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the world’s energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a larg…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…