Engaged in drying, pharmaceutical, food and other equipment manufacturing professional manufacturers

086-519-88608989

Overview:Working principleAfter the air is heated and purified, it is introduced from the bottom by the induced draft fan and passes through the perforated plate of the hopper. In the working chamber, fluidization is formed by the action of stirring and negati…

Working principle

After the air is heated and purified, it is introduced from the bottom by the induced draft fan and passes through the perforated plate of the hopper. In the working chamber, fluidization is formed by the action of stirring and negative pressure, the moisture is quickly evaporated and then taken away with the exhaust gas, and the material is quickly dried.

Performance characteristics

◎The fluidized bed has a circular structure to avoid dead ends.

◎The hopper is equipped with agitation to avoid agglomeration of wet materials and channeling during drying.

◎Using dumping and unloading of pellets, convenient, rapid and thorough, and automatic feeding and discharging system can also be designed according to requirements.

◎Sealed negative pressure operation, air flow is filtered. Easy to operate and easy to clean.

◎The drying speed is fast, the temperature is uniform, and the drying time of each batch is generally 20-30 minutes, depending on the material.

Adapt to materials

◎Machine screw extruded pellets, swing pellets, wet high-speed mixing and granulation pellets.

◎Drying wet granular and powdery materials in medicine, food, feed, chemical and other fields.

◎Large particles, small blocks, sticky blocks and granular materials.

◎Materials such as konjac whose volume changes during drying.

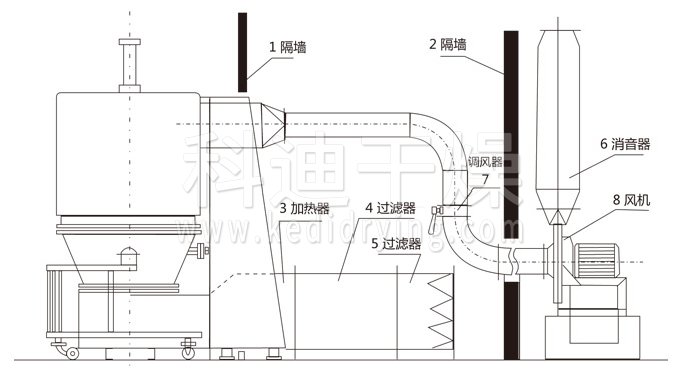

Schematic

Technical specifications

| Project | Model | ||||||

| Feeding (kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Fan power (kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 |

| Stirring power (kw) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Stirring speed (rpm) | 8~11 | ||||||

| Steam consumption (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Operating time (min) | 15-30(Revised according to material characteristics) | ||||||

| Host height | 2700 | 2900 | 2900 | 2900 | 2900 | 3300 | 3500 |

Among the many drying equipment, spray drying equipment is one of the most widely used drying equipment, which is a drying equipment for proc…

When granular materials are dried in an ordinary fluidized bed dryer, the particles of the materials should be uniform and have certain speci…

The fruits and vegetables are sliced and dehydrated to become dehydrated fruit and vegetable slices. After being vacuum packed, this kind of …

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the world’s energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a larg…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…